What we offer

Narutaki Industries stands at the forefront of custom precision bevel and miter gear manufacturing, boasting a rich legacy of expertise and innovation. Our Gear Division excels in the production of spiral bevel gears, catering to a broad spectrum of needs from prototype development and small batch production to full-scale manufacturing.

We have expertise and technology to manufacture small gears, achieving the highest precision in gear cutting to ensure our clients receive unparalleled quality. Our capabilities extend to a variety of machining products, including spur gears and helical gears, with the ability to work on modules up to 2 and diameters up to φ100. We work with a diverse range of materials such as S45C, SCM415, SCM420, SCM435, SCM440, SNCM420, and SUS304, providing flexible solutions tailored to our clients' specific requirements.

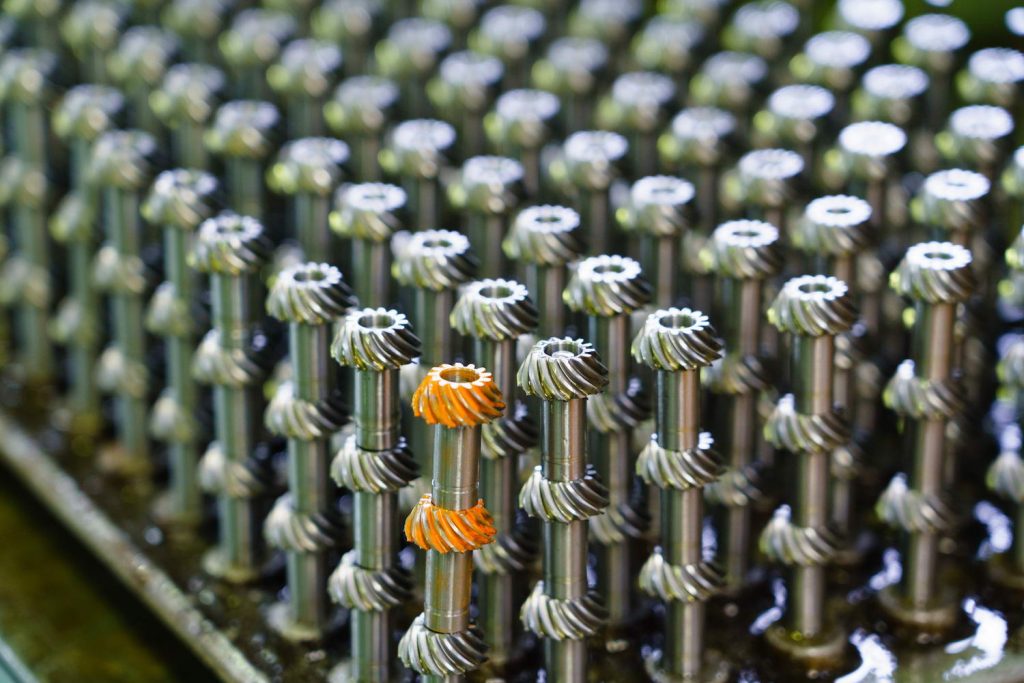

Gear mass production

Machinable Specifications

| Module | 〜4 (DP about 6.35 or less) |

|---|---|

| Outer Diameter | 〜120 mm (4.72 inches) |

| Product Shape | Custom |

| Spiral Angle (deg.) | 0〜40 |

| Material | Carbon Steel Alloy Steel Stainless Steel Copper Alloy Resin Plastic |

| Finish | Grinding or Cutting |

| Accuracy Class | JIS Class 0 (DIN Class4, AGMA Class13, ISO Class4) |

| Manufacturing Capacity (pcs/month) | 100000 pcs/month (Cutting), 1200 pcs/month (Grinding) |

| Manufacturing Equipments | Round bar cutting Lathe Machine (2axis 〜 5axis) Machining Center Broaching Machine Wire Cutting Machine Spiral Bevel Machine Hobbing Machine Cylindrical grinder Grinding (Spiral bevel) Machine |

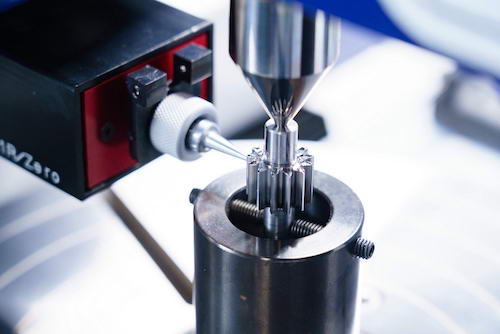

| Inspection Equipments | Gear Testing Machine (for Accuracy Class) Gear rolling tester Hardness tester All other testing equipment required for manufacturing |

Product Examples

Small Gear Sample 1

Small Gear Sample 2

Why choose us

1. CNC Machining Equipment

Our cutting-edge CNC machining equipment allows us to achieve exceptional precision and consistency in gear production. This technology ensures that every gear we produce meets the highest standards of accuracy and performance.

DMG 5-axis machining center at NARUTAKI

2. Gear Hobbing and Grinding Machines

We utilize advanced gear hobbing and grinding machines to produce gears with superior finish and accuracy. Our expertise in gear hobbing and grinding ensures that our gears have optimal performance, longevity, and reliability.

3. Metrology and Quality Control Equipment:

From small lots to mass production, Narutaki Industries is equipped to meet the diverse needs of our clients without compromising on quality or precision. Our flexible manufacturing processes, supported by our 5-axis machining capabilities and stringent quality control measures, allow us to scale production while maintaining the high precision required for critical applications in positioning and power transmission.

Gear quality inspection process at NARUTAKI

FAQs about Precision Bevel & Miter Gear Manufacturing

Q.1 What is the minimum teeth for a bevel gear?

The minimum number of teeth for a bevel gear generally depends on the specific design and application. However, for straight bevel gears, the minimum is typically around 12 teeth. This helps avoid excessive undercutting and ensures smoother operation.

Q.2 What is the smallest gear teeth?

The smallest gear teeth depend on the gear's application and material, but in general, micro gears can have teeth as small as 0.2 to 0.3 modules. These tiny gears are often used in precision instruments and small mechanical devices where space is at a premium.

Q.3 How many teeth does a small gear have?

A small gear can have as few as 10 to 20 teeth, depending on the design requirements and the intended use. In precision applications, these small gears are designed to operate smoothly and efficiently, despite their limited number of teeth.