Narutaki's Bevel & Miter Gear Grinding Service

At Narutaki, we specialize in the precision manufacturing of custom-made spiral bevel and miter gears. Our state-of-the-art gear grinding services are tailored to meet the highest standards of accuracy and performance, ensuring optimal functionality and durability for your specific applications.

With a rich heritage of craftsmanship and cutting-edge technology, Narutaki is dedicated to delivering superior gear solutions that cater to a wide range of industrial needs. Whether you require gears for automotive, aerospace, machinery, or any other industry, our team of experts is here to provide you with the perfect fit.

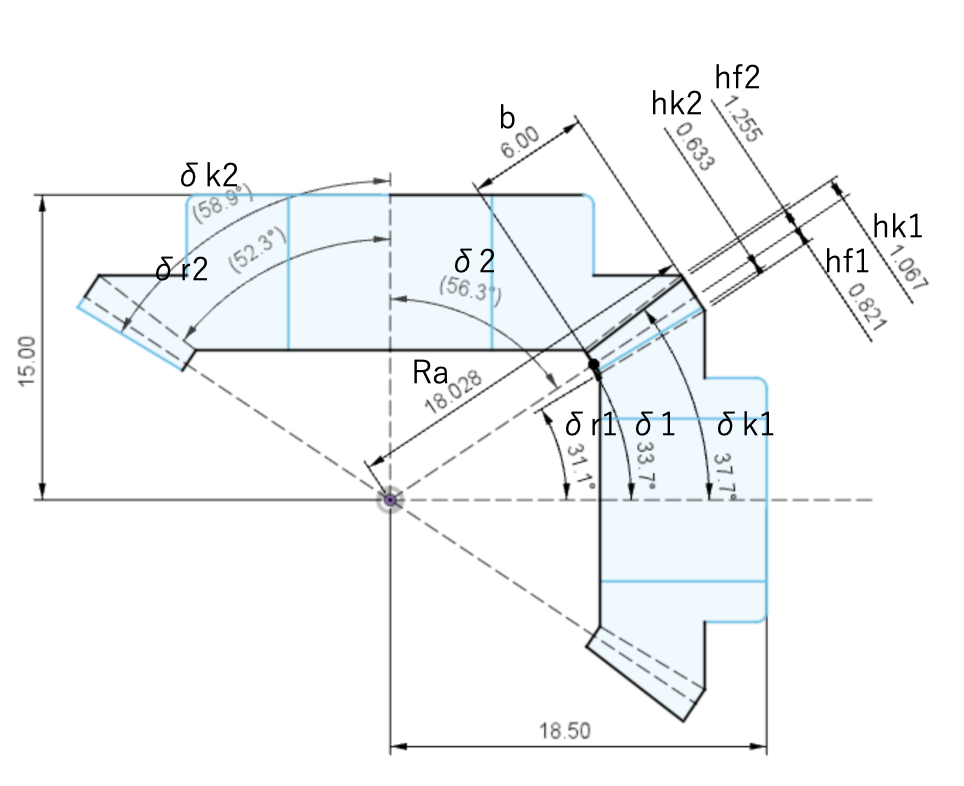

Gear Teeth/Profile Grinding Specifications

| Item | Specifications | |

|---|---|---|

| Number of Modules (max.) | 4 | |

| Diametral Pitch (min.) | 6.5 | |

| Outer Diameter (max.) | φ100 | |

| Available Material | Carbon Steel | S45C(AISI 1045) |

| Alloy Steel | SCM415(AISI 4115), SCM420(AISI 4118), SCM435(AISI 4135), SCM440(AISI 4140), SNCM420(AISI 4320) | |

| Stainless Steel | SUS304(AISI 304) | |

| Grinding Machinery | GBG-3210 MATRIX (Grinding wheel diameter ~ 3.5 inches) | |

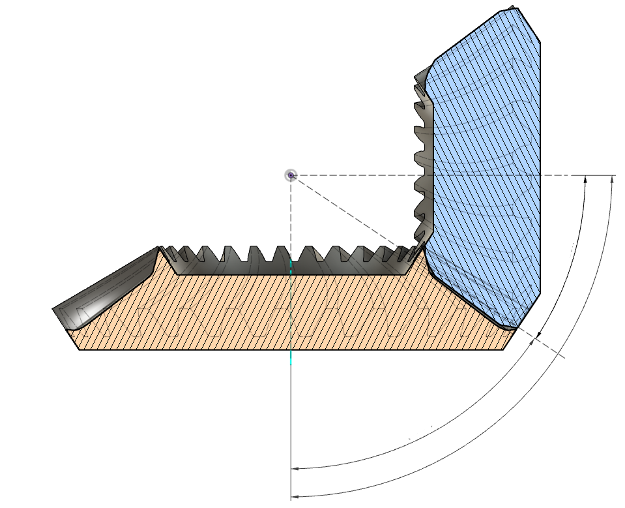

Narutaki's Gear Grinding Machinery

At Narutaki, we utilize the Matrix GBG-3210 Gear Grinding Machine to deliver exceptional precision and quality in our gear manufacturing processes.

Key Features of the Matrix GBG-3210:

- High Precision Grinding: The GBG-3210 ensures ultra-precise gear grinding, achieving tight tolerances and superior surface finishes for spiral bevel and miter gears.

- Versatile Capabilities: Capable of grinding a wide range of gear sizes and types, this machine provides the flexibility needed to meet diverse industry requirements.

- Advanced Control Systems: Equipped with sophisticated CNC controls, the GBG-3210 offers enhanced automation, consistency, and ease of operation, resulting in high-quality gear production.

- Robust Construction: Built for durability and reliability, the Matrix GBG-3210 can withstand rigorous use, ensuring consistent performance over time.

- Efficient Production: With its high-speed grinding capabilities and efficient workflow, this machine significantly reduces production times while maintaining the highest quality standards.

GBG-3210 (CNC Bevel Gear Grinding Machine)

Service Process

STEP 1: Inquiry

Start the process by reaching out to us with your specific gear grinding needs and requirements.

STEP 2: Consultation

Have a thorough consultation to discuss your technical specifications and application details, ensuring we fully understand your needs.

STEP 3: Quotation

Provide a detailed quotation, including cost estimates, timelines, and terms, based on our consultation.

STEP 4: Order Confirmation

Review and approve the quotation, then confirm your order and the agreed terms.

STEP 5: Design and Planning

Review your gear design and offer a comprehensive production plan to ensure precision and efficiency.

STEP 6: Gear Grinding

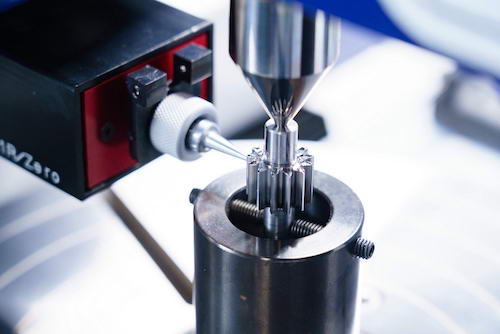

Perform precision grinding on your gears, achieving the required dimensions and surface finish.

STEP 7: Final Inspection

Conduct thorough testing and inspection to ensure your gears meet all specified requirements and quality standards.

STEP 8: Packaging and Delivery

Securely package your finished gears and coordinate logistics to ensure they are delivered to you safely and on time.

FAQs about gear grinding service

Q.1: What materials can Narutaki Industries grind for spiral bevel gears?

Narutaki Industries can grind spiral bevel gears made from a variety of materials, including high-strength alloy steels, carbon steels, stainless steels, and specialized materials tailored to meet specific industry requirements.

Q.2: What is the typical turnaround time for a custom gear grinding order?

The typical turnaround time for a custom gear grinding order at Narutaki Industries varies depending on the complexity and quantity of the gears. Generally, it ranges from 3 to 7 weeks from order confirmation to delivery. Expedited services may be available upon request.

Q.3: How do I request a quote for custom gear grinding services?

To request a quote for custom gear grinding services, please visit our website and fill out the online inquiry form with your specific requirements. You can also contact our sales team directly via email (info@en.naru-taki.com) or phone (+81 884-983-3630) for personalized assistance.

Q.4: What are the quality control measures in place for gear grinding at Narutaki?

At Narutaki Industries, we implement stringent quality control measures throughout the gear grinding process. This includes thorough material inspections, precise machining with state-of-the-art equipment, regular in-process quality checks, and comprehensive final inspections to ensure all gears meet our high standards and your exact specifications.

Q.5: How can I contact Narutaki Industries for more information or to place an order?

You can contact Narutaki Industries for more information or to place an order on our website using the contact form, emailing us at info@en.naru-taki.com, or calling our customer service team at +81 884-983-3630. Our team is ready to assist you with all your gear grinding needs.