What we offer

Narutaki Industries stands at the forefront of custom precision bevel and miter gear manufacturing, boasting a rich legacy of expertise and innovation. Our Gear Division specializes in the production of small-sized gears, with spiral bevel gears as our core offering, catering to a broad spectrum of needs from prototype development and small batch production to full-scale manufacturing.

We are committed to achieving the highest precision in gear cutting, ensuring our clients receive unparalleled quality. Our capabilities extend to a variety of machining products, including spur gears and helical gears, with the ability to work on modules up to 2 and diameters up to φ100. We work with a diverse range of materials such as S45C, SCM415, SCM420, SCM435, SCM440, SNCM420, and SUS304, providing flexible solutions tailored to our clients' specific requirements.

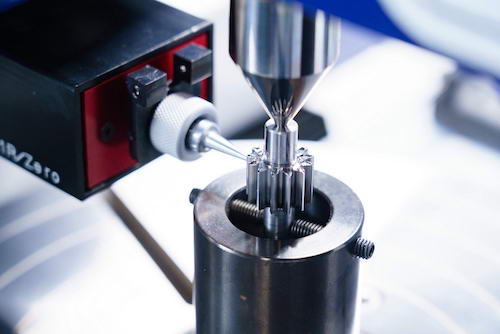

Precise gear grinding process at NARUTAKI

Machinable Specifications

| Module | 〜4 (DP about 6.35 or less) |

|---|---|

| Outer Diameter | 〜120 mm (4.72 inches) |

| Product Shape | Custom |

| Spiral Angle (deg.) | 0〜40 |

| Material | Carbon Steel Alloy Steel Stainless Steel Copper Alloy Resin Plastic |

| Finish | Grinding or Cutting |

| Accuracy Class | JIS Class 0 (DIN Class4, AGMA Class13, ISO Class4) |

| Manufacturing Capacity (pcs/month) | 100000 pcs/month (Cutting), 1200 pcs/month (Grinding) |

| Manufacturing Equipments | Round bar cutting Lathe Machine (2axis 〜 5axis) Machining Center Broaching Machine Wire Cutting Machine Spiral Bevel Machine Hobbing Machine Cylindrical grinder Grinding (Spiral bevel) Machine |

| Inspection Equipments | Gear Testing Machine (for Accuracy Class) Gear rolling tester Hardness tester All other testing equipment required for manufacturing |

Product Examples

Precise gear grinding

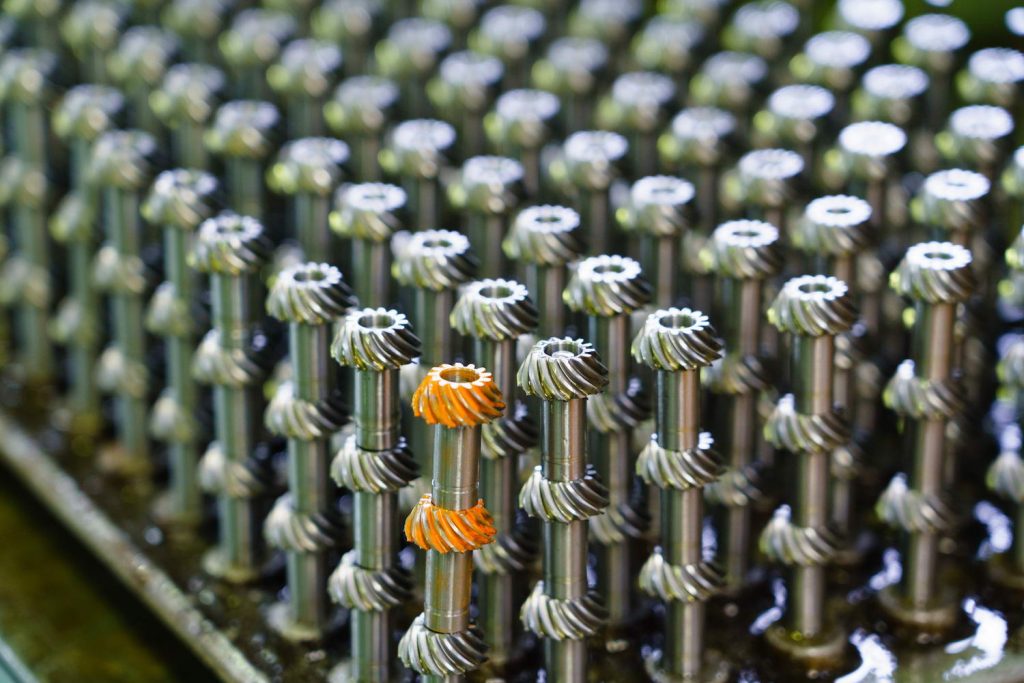

Precise gear cutting

Why choose us

1. 5-axis Machining Center

We leverage its advanced 5-axis Machining Center to push the boundaries of gear manufacturing precision. This technology enables us to achieve accuracy in gear pitch, ensuring that every gear, regardless of its application, meets the highest standards of precision. This is particularly crucial for gears used in positioning and power transmission, where exactitude is paramount.

DMG 5-axis machining center at NARUTAKI

Gear quality inspection process at NARUTAKI

2. Comprehensive quality control

Our comprehensive quality control system is at the heart of our commitment to excellence. By meticulously monitoring every aspect of our manufacturing process, we ensure that the precision of gear pitch is maintained across all products. This rigorous approach guarantees that our gears perform flawlessly in both positioning and power transmission applications, where the margin for error is virtually nonexistent.

3. Small lots to Mass production

From small lots to mass production, Narutaki Industries is equipped to meet the diverse needs of our clients without compromising on quality or precision. Our flexible manufacturing processes, supported by our 5-axis machining capabilities and stringent quality control measures, allow us to scale production while maintaining the high precision required for critical applications in positioning and power transmission.

Gear mass production

FAQs about Precision Bevel & Miter Gear Manufacturing

Q.1: What types of gears can Narutaki Industries manufacture?

Narutaki Industries specialize in the production of small-sized gears, with a core offering of spiral bevel gears. Our capabilities also extend to manufacturing spur gears and helical gears. We cater to a broad spectrum of needs, from prototype development and small batch production to full-scale manufacturing.

Q.2: What materials does Narutaki Industries use for gear manufacturing?

We work with a diverse range of materials to meet various industry standards and client requirements. Our material selection includes S45C, SCM415, SCM420, SCM435, SCM440, SNCM420, and SUS304, providing flexible solutions tailored to our clients' specific needs.

Q.3: What is the maximum module and diameter Narutaki Industries can work with for gear production?

Our manufacturing capabilities allow us to work on gears with modules up to 4 and diameters up to φ120 mm (or 4.72 inches). This range enables us to produce gears for a wide array of applications, ensuring precision and quality.