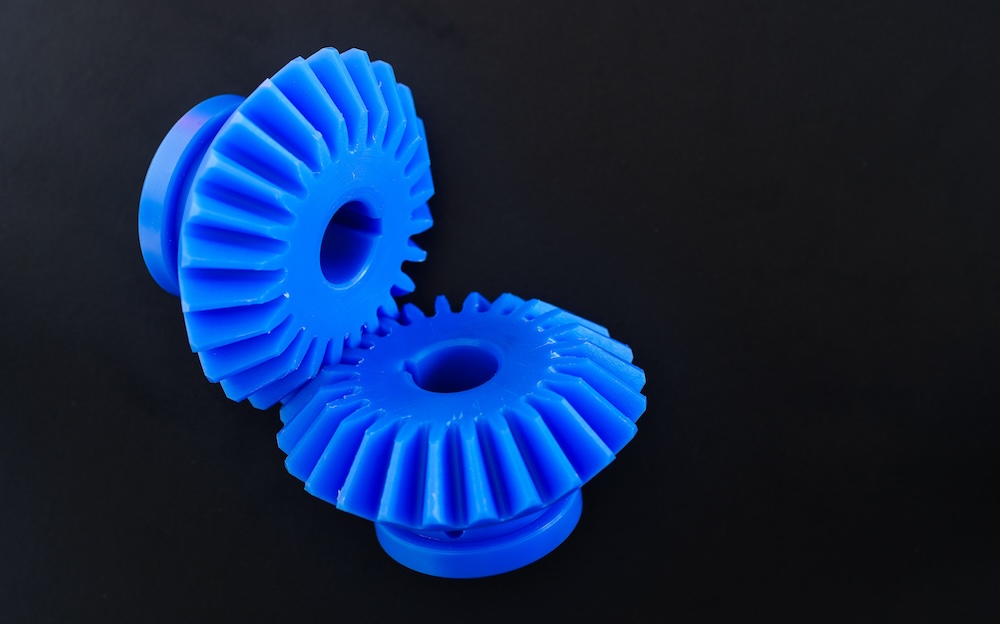

Small Plastic Bevel & Miter Gears

Narutaki Industries leads the way in custom small plastic bevel and miter gear manufacturing Our Gear Division specializes in producing high-precision plastic bevel gears, from prototype development and small batch production to full-scale manufacturing.

We excel in manufacturing small plastic gears, achieving unmatched precision in gear cutting, ensuring our clients receive the highest quality products. Our capabilities extend to various gear types, including spur and helical gears, with proficiency in handling modules up to 2 and diameters up to φ100. We work with a variety of plastic materials, offering tailored solutions to meet our clients' specific needs.

Machinable Specifications

| Module | 0.3 - 4 (DP about 6.35 or less) |

|---|---|

| Diametral Pitch | 6.5 - 80 |

| Outer Diameter | 6 - 120 mm (0.24 - 4.72 inches) |

| Product Shape | Custom |

| Spiral Angle (deg.) | 0 - 40 |

| Gear ratio | 1:1 - 1:10 |

| Material | POM (Polyoxymethylene) Nylon Other Engineering Plastics |

| Finish | Grinding or Cutting |

| Accuracy Class | JIS Class 0 (DIN Class4, AGMA Class13, ISO Class4) |

| Manufacturing Capacity (pcs/month) | 100000 pcs/month (Cutting), 1200 pcs/month (Grinding) |

| Manufacturing Equipments | Round bar cutting Lathe Machine (2axis - 5axis) Machining Center Broaching Machine Wire Cutting Machine Spiral Bevel Machine Hobbing Machine Cylindrical grinder Grinding (Spiral bevel) Machine |

| Inspection Equipments | Gear Testing Machine (for Accuracy Class) Gear rolling tester Hardness tester All other testing equipment required for manufacturing |

Material Options

Polyoxymethylene (POM)

Polyoxymethylene (POM), commonly known as acetal, is a highly durable engineering plastic renowned for its excellent mechanical properties. It offers high stiffness, low friction, and excellent dimensional stability, making it an ideal choice for small plastic bevel gears that require precision and strength. POM gears exhibit superior wear resistance and are well-suited for applications where smooth operation and long-lasting performance are critical.

Nylon

Nylon is a versatile and widely used engineering plastic known for its outstanding toughness and abrasion resistance. It provides excellent tensile strength and impact resistance, making it a reliable material for small plastic bevel gears that need to withstand heavy loads and harsh conditions. Nylon’s ability to absorb vibrations and reduce noise further enhances its suitability for various applications, ensuring smooth and quiet gear operation.

Other Engineering Plastics

We also offer a range of other high-performance engineering plastics tailored to specific application needs. These materials include, but are not limited to, advanced composites that provide enhanced heat resistance, chemical stability, and lightweight properties. Whether it's for extreme environments or specialized applications, our selection of engineering plastics ensures that we can deliver custom small plastic bevel gears that meet the most demanding requirements.

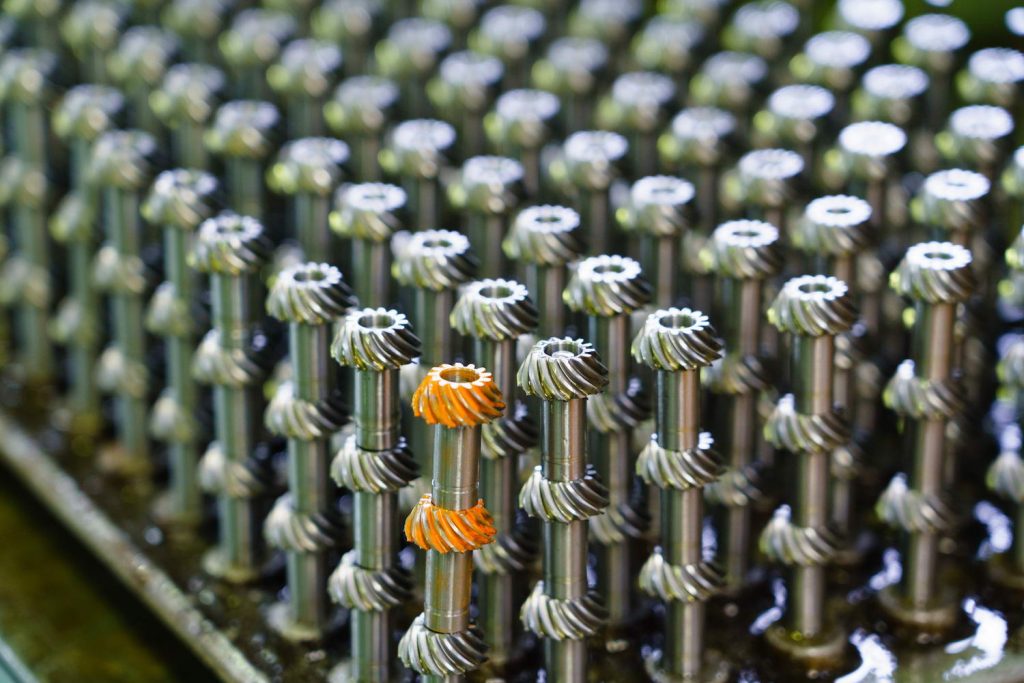

Product Examples

- Material: POM

- Module: 2.0

- Number of teeth: 30

- Helix angle: 35°

- Material: MC703HL

- Module: 2.0

- Number of teeth: 45

- Helix angle: 35°

Applications and Industry Use Cases

Robotics and Automation

Small plastic bevel gears are integral to the functioning of advanced systems like touch sensor gloves. These gloves, which are used to control robotic hands or other automated equipment, require precise and responsive movement to mimic human gestures accurately. The small plastic bevel gears in these gloves translate the user's finger movements into mechanical actions, allowing for delicate and precise control of the robotic system. The lightweight and flexible properties of plastic gears are particularly beneficial in this application, as they contribute to the glove's overall sensitivity and responsiveness without adding unnecessary weight or bulk.

Consumer Electronics

In consumer electronics, small plastic bevel gears are commonly found in devices such as cameras, where they enable the smooth operation of zoom lenses, focusing mechanisms, and other moving parts. The lightweight and durable nature of plastic gears makes them ideal for these applications, where compact size and quiet operation are essential. Additionally, their ability to be molded into complex shapes allows for seamless integration into the intricate designs of modern electronic devices, ensuring reliability and performance.

FAQs about Small Plastic Bevel & Miter Gear Manufacturing

Q.1 What is the minimum number of teeth for a small plastic bevel gear?

The minimum number of teeth for a small plastic bevel gear typically depends on the specific design and application requirements. For straight bevel gears, the minimum is generally around 12 teeth. This ensures smoother operation and minimizes the risk of undercutting, which is especially important in maintaining the integrity of plastic gears.

Q.2 What is the smallest gear teeth size available?

The smallest gear teeth size available for small plastic gears can be as fine as 0.2 to 0.3 modules, depending on the application and material used. These micro gears are commonly found in precision instruments and small mechanical devices, where space is limited and high accuracy is essential.

Q.3 How many teeth does a small plastic gear typically have?

A small plastic gear can have as few as 10 to 20 teeth, depending on the design and intended application. Despite the limited number of teeth, these gears are engineered to deliver smooth and efficient performance in precision applications, ensuring reliable operation in compact spaces.