Zerol Bevel Gear Manufacturing Service

What we offer

Narutaki Industries stands at the forefront of custom precision bevel and miter gear manufacturing, boasting a rich legacy of expertise and innovation. Our Gear Division specializes in the production of small-sized gears, with spiral bevel gears and zerol bevel gears as our core offering, catering to a broad spectrum of needs from prototype development and small batch production to full-scale manufacturing.

We are committed to achieving the highest precision in gear cutting, ensuring our clients receive unparalleled quality. Our capabilities extend to a variety of machining products, including spur gears and helical gears, with the ability to work on modules up to 2 and diameters up to φ100. We work with a diverse range of materials such as S45C, SCM415, SCM420, SCM435, SCM440, SNCM420, and SUS304, providing flexible solutions tailored to our clients' specific requirements.

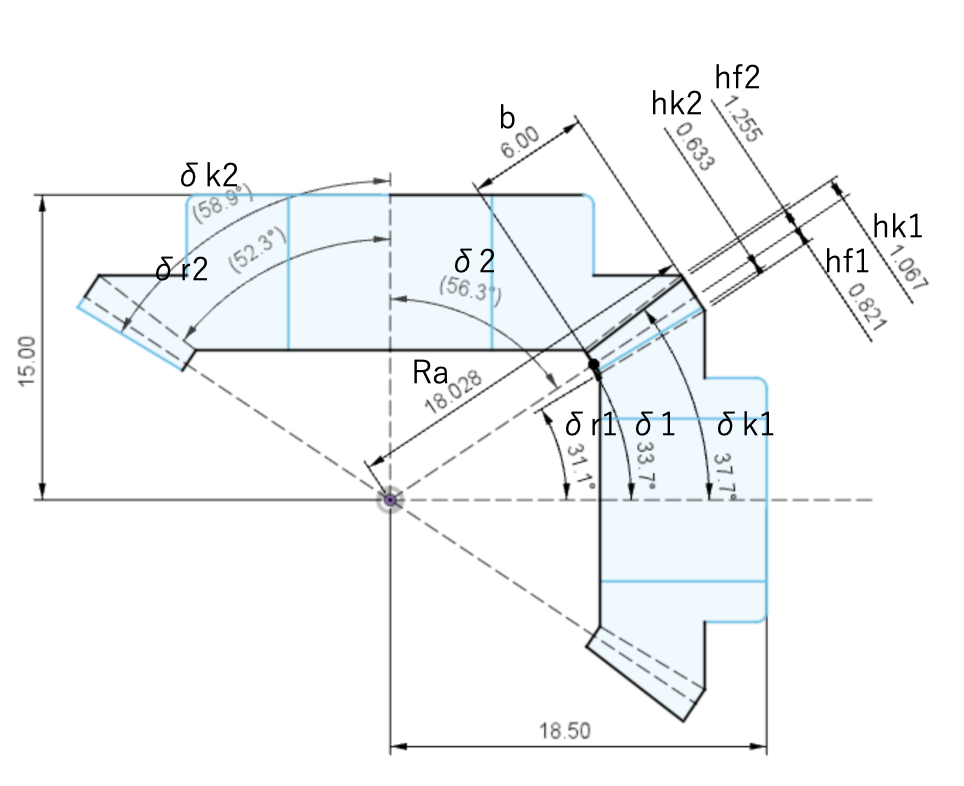

Zerol Bevel Gear Specifications

| Item | Specifications | |

|---|---|---|

| Number of Modules (max.) | 4 | |

| Diametral Pitch (min.) | 6.5 | |

| Outer Diameter (max.) | φ100 | |

| Machining Material | Carbon Steel | S45C(AISI 1045) |

| Alloy Steel | SCM415(AISI 4115), SCM420(AISI 4118), SCM435(AISI 4135), SCM440(AISI 4140), SNCM420(AISI 4320) | |

| Stainless Steel | SUS304(AISI 304) | |

| Machining Equipment | 5-axis multi-tasking machine DMG Mori, NTX1000 | |

| Spiral Bevel Gear SBG-10×11 | ||

| CNC Cylindrical Grinder, E300G | ||

| NC grinding machine for spiral bevel gears (module: ~4, DP: 6.5~) | ||

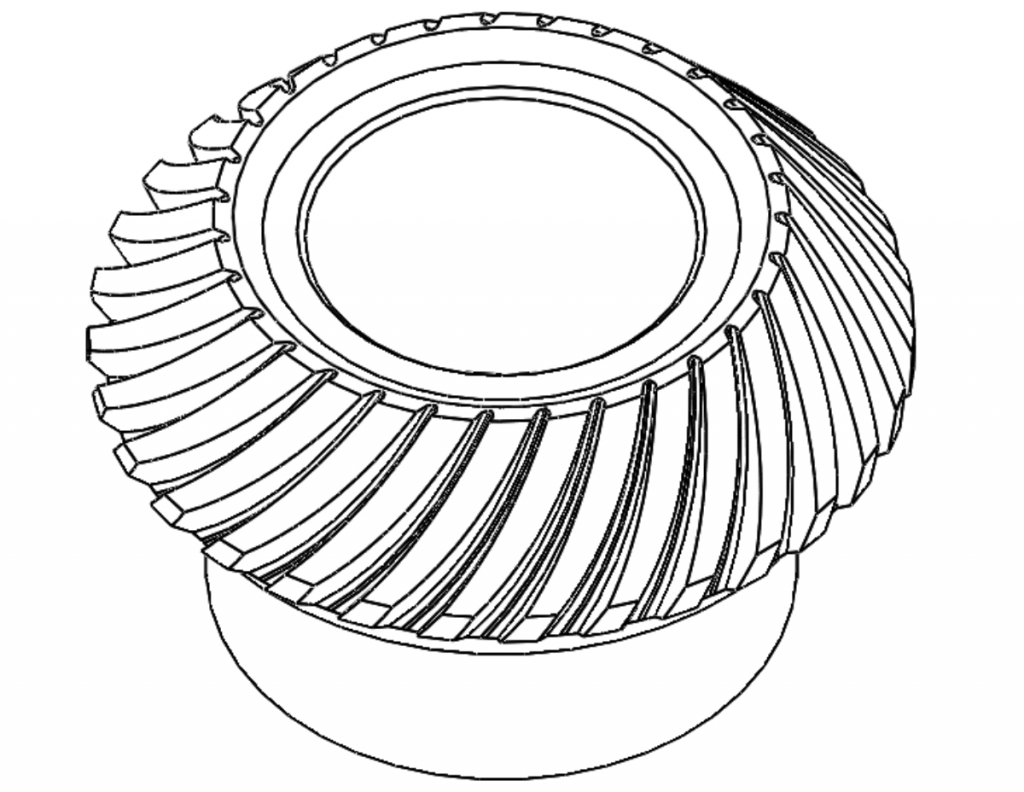

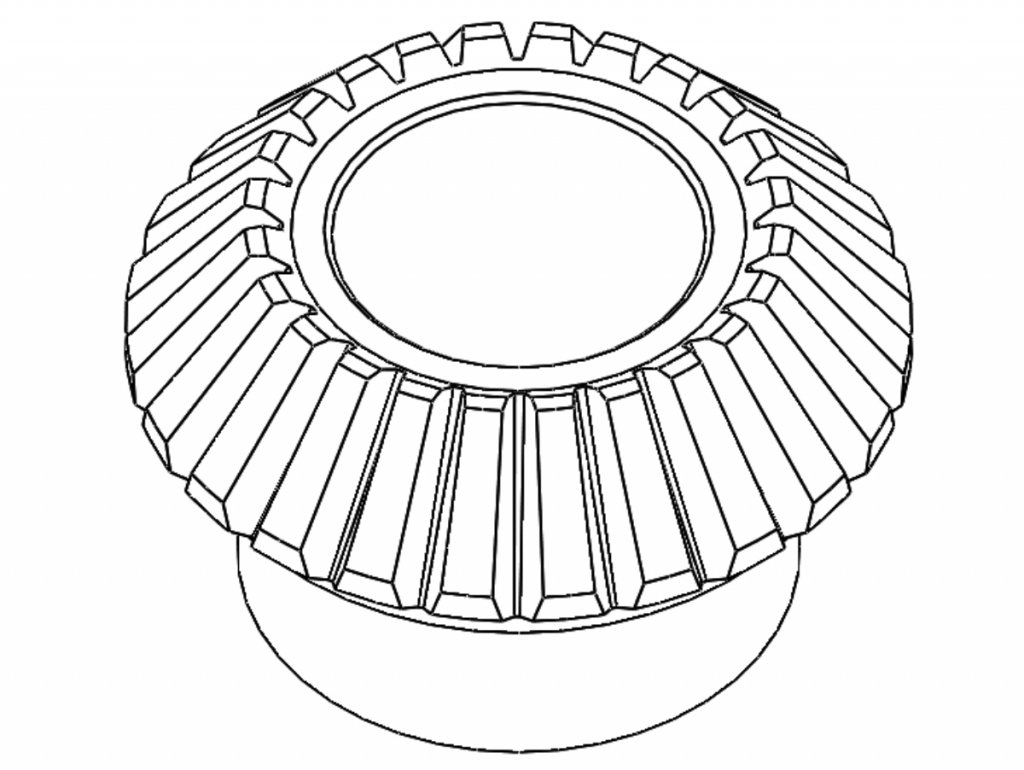

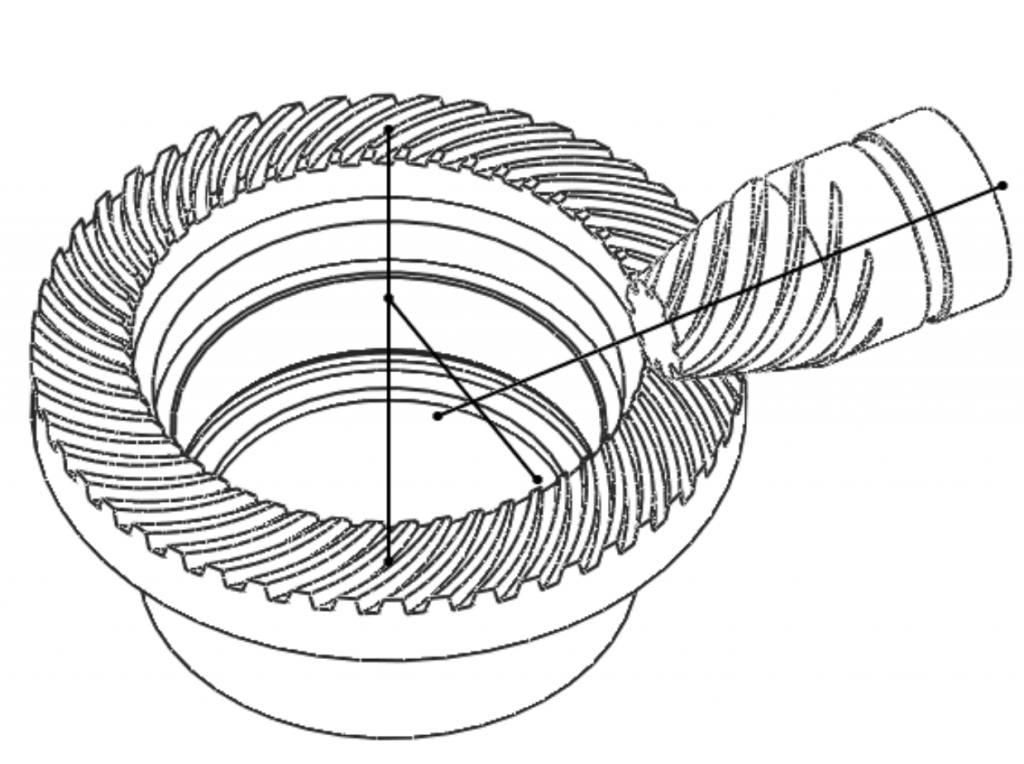

Product Examples

We can provide gears of the same material and size as spiral bevel gears.

FAQs

Q.1: Can you customize Zerol bevel gears to specific requirements?

A.1: Yes, we offer fully customizable Zerol bevel gears, including size, material, and tooth profile, to meet your exact specifications.

Q.2: What materials do you use for Zerol bevel gears?

A.2: We use high-quality materials such as alloy steels, stainless steel, and specialized composites to ensure durability and performance.

Q.3: How long does it take to manufacture Zerol bevel gears?

A.3: Production time depends on the complexity and volume of the order, but our state-of-the-art facilities enable fast turnaround times.

Q.4: How do you ensure the quality of Zerol bevel gears?

A.4: We use advanced CNC machines, rigorous quality control measures, and high-quality materials to ensure consistent and reliable performance.

Basics of Zerol Bevel Gears

Definition

Zerol bevel gears are a type of bevel gear characterized by their curved teeth and intermediate spiral angle. Unlike straight bevel gears with linear teeth or spiral bevel gears with fully curved teeth, Zerol bevel gears blend the advantages of both designs. This unique geometry offers:

Smooth Transmission: Minimal vibration and noise during operation.

Enhanced Durability: Reduced stress concentration for prolonged lifespan.

Flexibility in Alignment: Suitable for applications with slight misalignments.

What does "Zerol" mean?

The term "Zerol" refers to the specific design characteristic of Zerol bevel gears, where the spiral angle of the teeth is close to zero degrees but still slightly curved. This intermediate angle provides a blend of the advantages seen in straight bevel gears (simple design and manufacture) and spiral bevel gears (smooth operation and quiet performance). This unique geometry allows Zerol bevel gears to deliver efficient power transmission with reduced noise and vibration, making them suitable for various precision applications.

Differences from Other Gears

vs. Spiral Bevel Gears

Zerol bevel gears have curved teeth with a near-zero spiral angle, offering a balance between the simplicity of straight bevel gears and the smoothness of spiral bevel gears. They produce moderate noise and are suitable for moderate loads and slight misalignments.

In contrast, spiral bevel gears feature fully curved teeth with a significant spiral angle, enabling quieter, smoother operation and higher load capacity, ideal for demanding applications like automotive differentials and gearboxes.

Therefore, Zerol bevel gears are less suitable for high-speed rotation compared to spiral bevel gears.

vs. Straight Bevel Gears

Zerol bevel gears have slightly curved teeth with a near-zero spiral angle, combining the simplicity of straight bevel gears with reduced noise and vibration. They offer smoother operation and better tolerance for slight misalignments. Straight bevel gears, on the other hand, have straight teeth that intersect at a central point, making them simpler and more cost-effective but noisier and less efficient under high loads or misaligned conditions compared to Zerol bevel gears.

vs. Hypoid Gears

Hypoid gears have offset axes, allowing the drive shaft and driven shaft to be non-intersecting, which is ideal for lowering the center of gravity in vehicles. They provide smoother, quieter operation with high torque transmission. In contrast, straight bevel gears have intersecting axes with straight teeth, offering simpler design and cost-efficiency. However, they produce more noise and vibration and are less suitable for high-torque applications compared to hypoid gears.

Applications of Zerol Bevel Gears

Automotive industry

Zerol bevel gears are integral to the automotive industry, enhancing performance and efficiency. In differential systems, they distribute torque smoothly for stable cornering. In steering systems, they provide precise motion for better control. For transmissions, they enable seamless gear shifts with reduced noise and vibration. Additionally, in electric and hybrid vehicles, they minimize drivetrain noise, ensuring quiet, efficient operation. Their durability and adaptability make them essential in modern automotive designs.

Engineer calibrating robotic arm in advanced manufacturing facility

Industrial machinery

Zerol bevel gears are essential in industrial machinery, providing smooth, efficient power transmission with reduced noise and vibration. They are widely used in gearboxes for heavy-duty equipment, ensuring reliable torque transfer under high loads. Additionally, Zerol bevel gears enhance performance in conveyors and material handling systems, ensuring durability and consistent operation in demanding industrial environments. Their adaptability supports various machinery designs.

Power tools

Zerol bevel gears are crucial in power tools, offering efficient torque transfer with minimal noise and vibration. In cordless drills and angle grinders, they ensure smooth power delivery for precise and reliable performance. Their durability and ability to handle high torque make them ideal for heavy-duty tools, extending tool life. Additionally, their compact design supports ergonomic and space-efficient tool configurations, enhancing functionality and user comfort in a wide range of applications.

Robotics

Zerol bevel gears are vital in robotics, enabling precise motion control and efficient power transmission. They are widely used in robotic arms and joints, ensuring smooth and accurate movements with minimal noise and vibration. Their compact, durable design supports space-constrained robotic systems, making them ideal for advanced automation in manufacturing, healthcare, and logistics, where precision and reliability are critical.

Agricultural machinery

Zerol bevel gears play a key role in agricultural machinery by providing reliable, efficient power transmission under heavy loads. In tractors and harvesters, they ensure smooth torque transfer to drive systems, improving performance. For rotary tillers and mowers, they enable precise, durable operation, enhancing cutting and tilling efficiency. Their robust design and noise-reducing capabilities make them ideal for grain conveyors and fertilizer spreaders, ensuring consistent performance in demanding agricultural applications.

Selection Guide

Load Requirements

When selecting gears, understanding the load requirements is crucial. Zerol bevel gears are ideal for moderate to high torque applications, providing smooth power transfer and durability. For applications with heavy or variable loads, choose materials like alloy steel for enhanced strength. If your load requirements are lighter or involve intermittent operation, consider cost-effective materials such as plastic composites. Proper load analysis ensures that the selected gears operate efficiently and maintain a long service life without premature wear or failure.

Speed Considerations

Speed plays a significant role in gear performance and material selection. Zerol bevel gears are suitable for moderate-speed applications due to their near-zero spiral angle, which balances efficiency and durability. For high-speed operations, spiral bevel gears may be more suitable due to their smoother tooth engagement. Additionally, high-speed applications may require heat-treated or precision-machined gears to reduce wear and maintain stability. Always consider the rotational speed when selecting gears to ensure optimal performance and noise reduction.

Alignment and Shaft Orientation

Zerol bevel gears require precise alignment for efficient operation but tolerate slight misalignments better than straight bevel gears. They are designed for intersecting shaft configurations, making them ideal for applications requiring compact and precise layouts. For more complex systems or when shafts are not perfectly aligned, consider gears with higher tolerances or coupling mechanisms to ensure smooth power transmission. Proper alignment minimizes vibration, wear, and energy loss, enhancing the gear's longevity and performance.

Material Selection

Material choice greatly impacts the durability, weight, and cost of gears. For heavy-duty applications, alloy or hardened steel provides superior strength and resistance to wear. Stainless steel is ideal for corrosive environments, while plastic or composite materials are excellent for lightweight, low-load applications requiring quieter operation. The operating environment, load, and speed requirements should guide material selection to ensure that the gears meet performance expectations while maintaining cost-efficiency.